Or: How to spell LM 317? And: Why is the correct spelling so important?

This is about the quality of data with regard to manufacturers part numbers: Why is it so important and so profitable to spell all of them correctly, and where to find the dictionary?

My last 2 articles described:

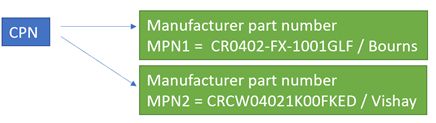

- AMPL: What is it?: The link between a company part number (CPN) and the manufacturing part numbers (MPN)

- A PDM system should be the repository for it.

So we need:

- The Company part number (CPN), connected to one or several:

- Manufacturer name(s)

- Manufacturer part number(s)

This information was entered into your PDM system using free text fields during the last decades (or are you working with Excel sheets still?!)

You might think: „Well, fine, this is how other companies do as well”, BUT

This is not the level of quality needed to create additional profit from this big set of data, nor to avoid upcoming catastrophes.

How to achieve a common (and profitable) spelling

Whenever you are unsure about spelling a word, you are consulting a dictionary, right?

Talking about (electronic) components: Let’s use one common dictionary as well, so that the same manufacturer part number (MPN) is always written the same way.

Only in case the MPN’s are written correctly, tools like SiliconExpert will be able to provide us their knowledge.

Logical conclusion: Use SiliconExpert as dictionary.

Benefit #1: Information about your electronic components on your fingertips

If your MPN naming is in line to the „SiliconExpert dictionary“, you gain information on each part immediately, such as:

- Part will have its last time buy very soon!

- The life cycle is only 2 years still. Not a good idea to see it inside an NPI bill of material.

- Alternatives

- Budgetary price

- ROHS III, REACH, California Prop65, TSCA, … compliance

- Online stock quantities world wide

- Plus whatever is important for you

The worst case that could happen if you are running electronics manufacturing plants is to miss a discontinuation notice – since this might stop your production all at a sudden and in worst case for a couple of months.

If all your MPNs are linked to the SiliconExpert database, it should not happen anymore.

If setting up such a big VECE system internally seems being too complicated for you: My recommendation is to use Am-Sys

The tool interfaces to SiliconExpert ,does all the detection, where used etc. It also offers a professional workflow to manage and mitigate the situation.

Benefit #2: compare prices for the same MPN listed under different CPN‘s

If all your MPNs are verified by using the same dictionary, it’s easy to compare prices for different CPN’s (Company part numbers) but being the identical manufacturing part. Distributors will not tell you that they are ripping you off by selling the same part to you – under another CPN for a higher price, maybe into a different factory. That’s your job to find out, and it’s almost like a “money printing machine”

You might ask yourself: Why should a company run the same component several times using different CPN’s?

This usually happens by company acquisitions, if their part numbering system is kept, or if you have several design authorities distributed worldwide, not managed by one single and strong Component Engineering group.

How to start?

If you consider using SiliconExpert as a service, simply ask for an “initial analysis”. You will find all your MPNs categorized as:

- All fine. Part number and manufacturer name was found in the SE database exactly as written

- Maybe a typo? (inside the Manufacturers name or the MPN), did you mean….instead?

- No idea what you are talking about here

Do not despair if this analysis looks bad. The number of “direct matches”, means: all your MPNs written exactly correct might not exceed 10..20%. Even if you turn a blind eye and accept the propsals in case 2), such as:

- NEC Electronics is Renesas now

- LM317 T(only ROHS) à ignored the addendum, it doesn’t seem to be a part of the MPN

Your success rate might not exceed 40..50%. Not seen anything better than 70% till date.

Now we know what’s written incorrectly. How to fix it?

The best course of action is always to fix it at the “source of truth”, means: Directly inside your PDM system. My experience however is that mass changes and PDM systems are somehow “mutually exclusive”.

So, what’s Plan B?

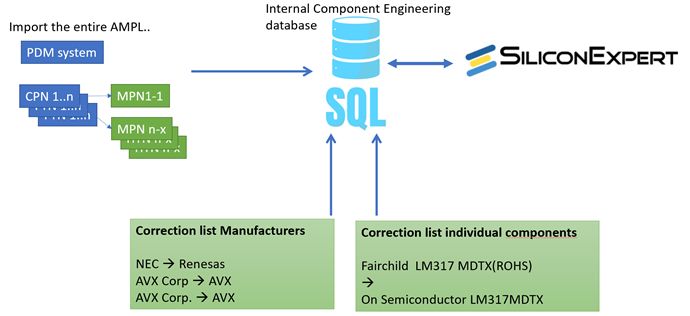

Create 2 correction lists:

Correcting manufacturer’s names

From: Manufacturer (as found in the PDM system) à Manufacturer known by SiliconExpert

This could be mergers of different “dialects”, such as: AVX Corp / AVX Corp. / à AVX

Or correcting formerly entered names, aquired meanwhile: NEC à Renesas.

This list alone might fix 75% of all cases. Creating it is straightforward and can be accomplished in a few days applying some tricks. Just ask me for the tricks or let me help you.

Individual correction of manufacturers part numbers

This is to fix one specific component: both the manufacturer name and the part number

Your system might look like this:

Now we got it all updated. How to sustain it?

- Only let good NPI parts into your PDM system

Allow to enter Manufacturers and MPNs into your PDM system that have been “spell checked”

But, please don’t expect wonders on improved data quality. As to my experience, the amount of renewal is on +5% annually. That’s why the correction lists are essential to correct the big mass first.

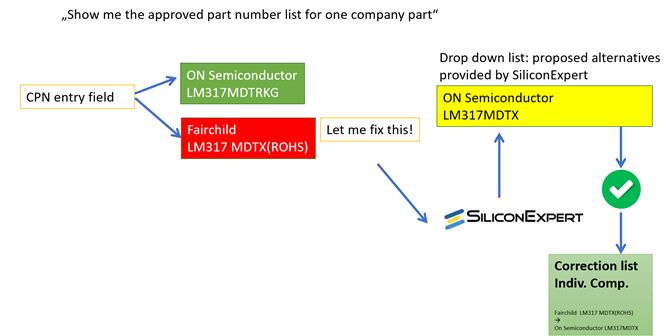

- Everybody to lend a hand

Once having installed a component engineering database, you will most likely have a web form to show the AMPL for one CPN to your users. It’s beneficial to add a “correction button” right here:

Takeaway

Don’t underestimate the importance of quality of data inside your AMPL. Use the database of a specialist like SiliconExpert.

This ensures that you are not caught off guard by a discontinuation.

Transform your new set of data into profitable information

Automate time consuming work like: “Are all my 23.000 finished goods ROHS III compliant?”

Use professional services such as Am-Sys

Last not least: Let me help you. Just call.

Pingback: [EN] Component Engineering begins as soon as price negotiations failed – Vece-Consulting

Die Kommentarfunktion ist deaktiviert.