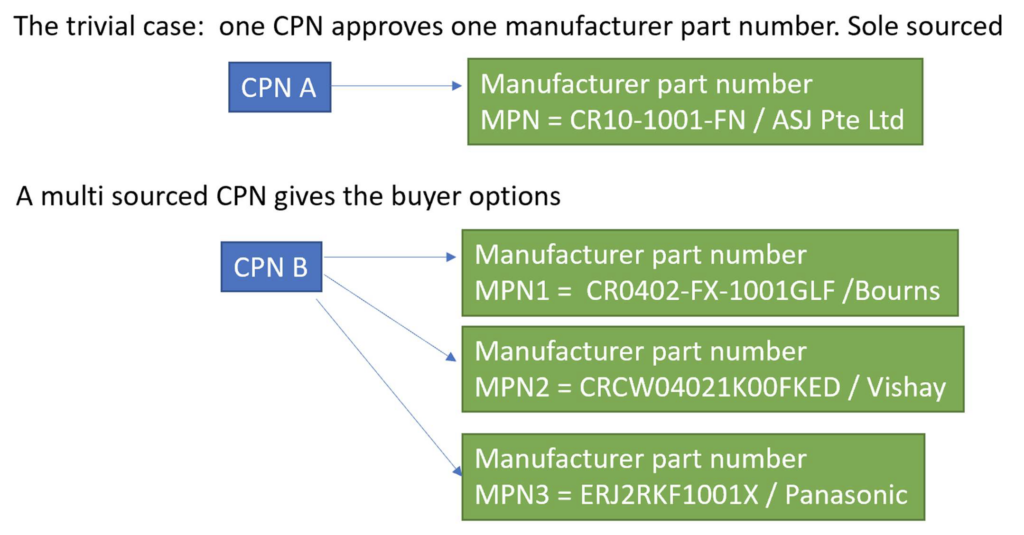

AMPL stands for: „Approved manufacturer parts list“, or: which manufacturer part numbers are released by R&D for one CPN (=Company Part Number). Sounds easy, or?

This definition answers the first question already: „who is responsible for the content “? It must be R&D, as they have verified that the finished goods are working well with those released components. Second approver group could be the Component Engineering group, having approved a second, cheaper source.

You might find in some companies where the AMPL for a component says: „any“, means: Dear sourcing, buy whatever you like – as long as it is a 1K Ohm 0402 1% tolerance resistor. This might be ok for the simplest components such as resistors, however, I wouldn’t do it. Staying with the example of a 1K resistor: This 1% tolerance can creep up to 3% in case of cheaper thick film resistors, or it can stay in 1% limits using thin film. Whereas it doesn’t play a role for a LED series resistor, it could be beyond the tolerance for a voltage divider in a power supply already.

If you are dealing with capacitors, you know it is getting even a bit more complicated.

Properties like reel size aren’t relevant for the design engineer, as it has no influence on the electrical properties. This is up to production, maybe the pick & place machine has a limit on the maximum reel size.

Take away: Each single CPN, even if it’s simple chicken food, has to have an AMPL. We will see the benefit in a bit, when we will be looking into identical parts under different CPN‘s

Let’s stay at the 1K Ohm resistor Talking about

Talking about the AMPL, let’s jump into real life right away

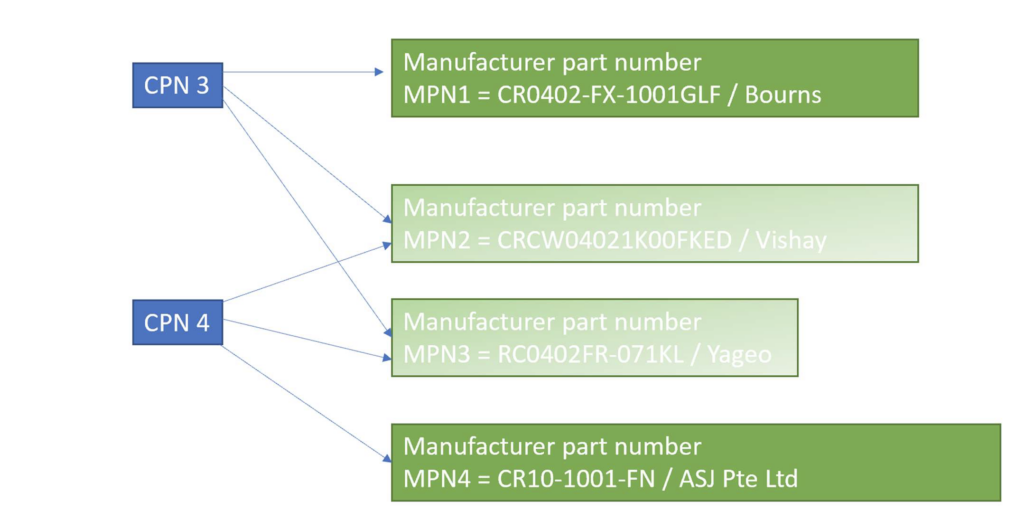

What we can see here are 2 different CPN’s, defining components having an identical function – however, their AMPL overlaps only partly. Doesn’t seem to make sense, right – but you can see it in big companies often, even in a much more complex version. It hasn’t to do with logic, more with: “that’s how it became during the years, with all those mergers and acquisitions, various engineering sites etc!

Disadvantages:

– More CPN’s are to be maintained, purchased and to be set up at the pick & place machine

– Smaller volumes resulting in higher prices

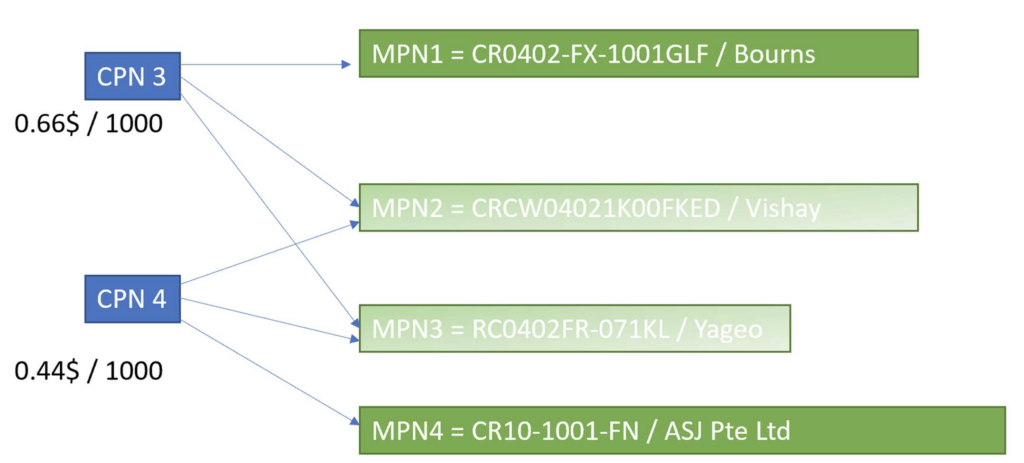

Now, get excited: How to make money from here?

CPN 4 is being purchased cheaper, but: which of the 3 approved MPNs is it?

Case 1: if the better price is achieved by purchasing MPN 2 or MPN 3

–> done deal for sourcing. MPN’s are released already by R & D for CPN 3 as well. Go and get the money!

Case 2: if the better price is achieved by purchasing MPN 4

–> Create a little Component Engineering project! Up to R & D approving MPN 4 for CPN 3 in addition this has a good chance for success, as MPN 4 is working well for CPN 4 already.

Prerequisistes:

The entire system works only, if all MPNs are checked by a “common dictionary”. My proposal: Take SiliconExpert as dictionary. If you validated the MPNs and manufacturer names in SiliconExpert, you are opening the entire world of information: life cycle, information on last time buy, ROHS compliance, crosses etc. More on that in a later article.

Advantages:

- One of the cornerstones for quality to ensure each single device in series production is working as expected

- Get to know your potentials for optimizing cost

- Crystal clear definition for sourcing

- Gold nuggets for the Component & Value engineering group

- Stock transfers on no longer needed (or urgently needed components) from factory A to factory B is

- possible only when you have a clean AMPL in place

Summary, IMHO, it is mandatory to maintain an AMPL for each single component thoroughly. This AMPL shouldn’t be created on free text entry fields, but validated by a “spell checker”, i.e. SiliconExpert. If you have a big mass of existing (bad quality data) entries: use correction lists. R & D is responsible for the AMPL. Who else can make sure that the component X under CPN Y is working well in finished good Z reliably. A CPN and its AMPL must be global, regardless of R & D group or factory. More on this in a later article.