Your ERP system might tell you which of your components are hanging around since months or even years in your stock. Or you simply notice some carton boxes having an inch of dust on top 😊.

The reasons might be various:

- Related products are low on sales, or obsoleted already

- Purchased too much as of overoptimistic forecasts (which I know never occurs in your company)

- NPI ramp up delayed, last minute changes in BOM or cancelled product introduction

However, you might want to get rid of this inventory, but how?

If you remember my earlier article on the contrary situation: “Part shortage, how to find some”, similar actions could be taken:

The easiest: Is there another factory in your company using the same CPN = Company part number?

Well, this sounds almost too easy. However, such a case might have been overlooked and the check might not have been executed.

Plus there is a second trap: Does the same CPN refer in each factory to the same MPN’s (=Manufacturing part numbers)? If not, the parts might not be useable in factory B. My recommendation: an AMPL (=Approved manufacturer parts list) for each CPN must be global, because.. read here)

Next level: Does another production site use the same manufacturer part under a different CPN?

In this case it is more than likely that a buyer or planner does not see the opportunity of re-use. However, this does not seem to make any sense, right? Why should a company have the same manufacturer part running under different company part numbers? In fact, it DOES happen, I have seen it quite often. The reasons are various and worth another article. Having a professional Component Engineering system in place will identify the opportunity by pressing a button.

Other options:

- Check if your excessive part is an upgrade of existing parts. Example: Re-use your 0.1% resistors for CPNs calling out for a 1% or 5% type. The same story applies for capacitors of higher voltage, faster microprocessors, wider temperature range etc. You name it.

- Even a redesign of the printed circuit could be considered if we are talking about an excessive value above 50.000$. Imagine the same part, just with a slightly different footprint. I almost hear R&D saying: “no way”, but: make the math yourself honestly, it could pay off.

You are at the end of the list and still sitting on tons of dead inventory?

Go and sell it.

Step 1: Check the value of your inventory: if it is worth 20$ – the action is simple, right?

Step 2: Check if the parts are active still or obsolete already. Obsolete parts could be worth gold

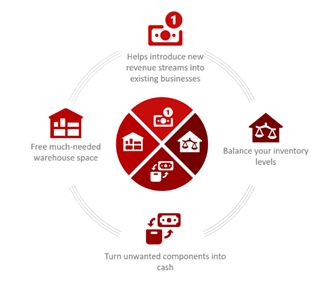

Step 3: Ask your distributor. Here is one: Win-Source.net They will seriously check your list of excessive material and get you a fair price. Find the process and the first easy step to be taken on this page: https://www.win-source.net/excess-inventory-management.html

Again, here are the reasons why you should do it: (Screenshot from the page above)

Takeaway

Don’t let your stock get dusty.

Re-use it by the help of your Component Engineering team

Get rid of it and make money

Check out for Win-source what it is worth being sold.

And, if you do not have all the information on your fingertips like a full and well-maintained AMPL: Think about improving your data. Ask Volker for help. VECE-consulting.com