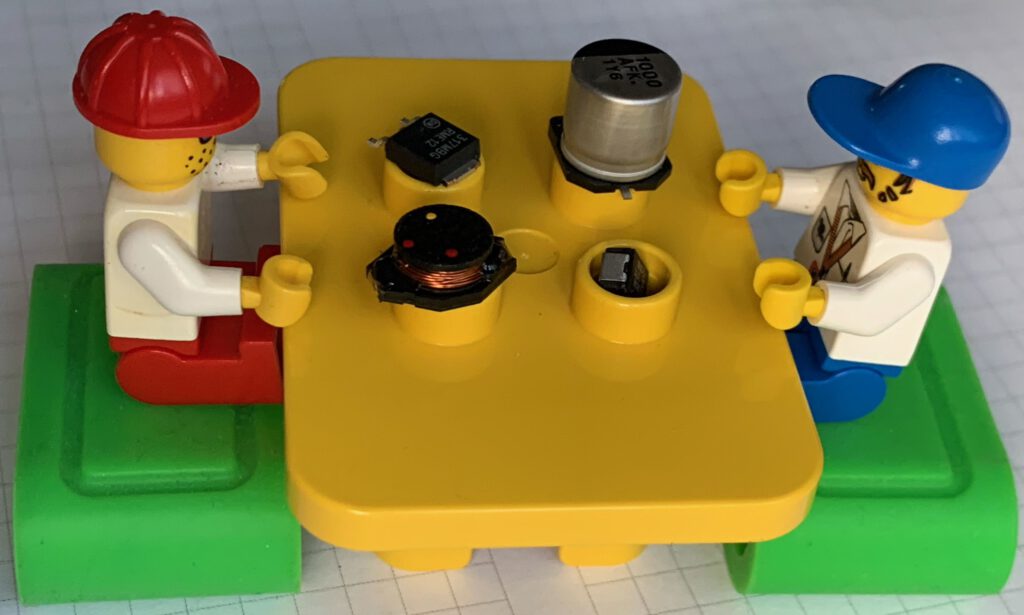

Maybe you were part of a group of people in your company, negotiating prices of electronic components with manufacturers? Maybe it ended successfully, maybe not and the prices stayed the same or even increased.

Where negotiations end, component engineering begins – and may still end up in a win-win situation. In detail:

Sourcing can negotiate components only having been approved by R&D, but often:

- The current manufacturer A has cheaper alternatives that have not been released (yet).

- Manufacturer B can offer compatible components that have exclusively been released by manufacturer A so far.

regarding 1) Same manufacturer, do alternatives exist?

As a representative of component engineering, at the table with lots of buyers and representatives of suppliers, especially after unsuccessful price discussions, I am always asking the question:

„Since you can’t do anything about the price of the given component: What is your next best alternative“?

The usual answers are:

- Do you require the full functionality?

- There might be variants / subsets of the component, without certain functions which you don’t require anyhow. Example: Microcontroller without USB interface you’re not using.

- Do you require the full temperature range?

- You might fall into the usual trap and say: „Yes, we are selling an end device that really has to work down to -40 degrees and up to +80 degrees. But often these are small volumes, so it’s worth splitting the one component into two company part numbers: a) cheap, highrunner b) expensive, lowrunner

- You are using a stone aged chip. Don’t you like to change?

- Do not limit yourself to: „the other component isn‘t FFF= Form, Fit, Function compatible. Instead, ask yourself: „What is the payback period redesigning for the other / newer component? This can be a layout change of the PCB, or „only“ an adjustment of the firmware or a release test in the EMC cabin. If the investment in R&D is paid back in less than 12 months: What’s stopping you? No resources? No excuse! Outsource the work…

But now to the far more exciting topic:

regarding 2) is there a different manufacturer offering an FFF compatible component, cheaper?

Or: How to get manufacturer B to deliver really good savings on a silver plate

The question you might want to ask whilst the negotiation: We will be able to send you a list of manufacturer part numbers / company part numbers, on which you are NOT released yet. Can you quote your alternatives for us?

This can be time consuming for you, so, here is the method to find your „candidates“ in less than one hour:

Let’s do a quick excursion to SiliconExpert.

Assuming your AMPL (=Approved Manufacturer Part list) is in good shape, you know the MPN = manufacturers part numbers released for a given CPN = company part number, typos are fixed. Read more about it here

In this case, your MPNs will be found in SiliconExpert. Lots of part properties are now on your fingertips fully automated, such as: life cycle, obsolescence information, ROHS compliance, AND…. The so called “Taxonomy path”

Taxonomy path is a hierarchical categorization for each component. Examples:

- Resistors > Fixed Resistors > Resistor Fixed Single-Surface Mount

- Capacitors > Fixed Capacitors > Capacitor Aluminum

- Diodes, Transistors and Thyristors > FET Transistors > MOSFETs

Now, we are finally coming to the method that has proven to be successful:

Step 1: Send to manufacturer

- A list of all taxonomy path’s of all your purchased components. Just those.

- Ask the manufacturer to tick all of them, where he thinks to have a competitive offering.

Step 2: Filter your purchasing list by:

- All records for the ticked taxonomies.

- Having good volumes or $$ value – well, a CE project should be worthwhile.

- New manufacturer is NOT released yet.

- Send currently released manufacturer / manufacturer part no and annual volumes.

Step 3: Ask the manufacturer

- To list his FFF compatible components.

- If his parts are non-FFF: let him tell what’s different.

- And a price quote of course.

Step 4: Pick the cherries

- As usual, the CE savings are super simple to compute: volumes x (current price – new offer)

- Should a line item result in good savings, (say: 1000$ +), why don’t you start a small CE project, intended to add / approve the new part to your existing AMPL underneath your CPN

You can find more about payback in one of my earlier blog articles about component & Value engineering in general. The methods in case of part shortage are applicable as well, read here

As usual I am very keen on your feedback – especially if you applied the method as well and if it was as successful as it was for me – And: happy to help and support you.