Your production came to a hard stop, because one out of 700 components is missing to build a finished good. You checked the usual search engines already, such as:

- WIN-SOURCE.NET

- SiliconExpert

- Findchips

- Octopart

- Z2Data

Nothing found, or the price was horrifying

What now?

You can follow these instructions manually or you can automate them.

They are sorted by effort: The easiest is action #1. If you weren’t successful, try #2 etc.

Action1: Is there any inventory in one of your other factories on the same Company Part Number (=CPN)?

This is the trivial case: the same company part number (=CPN) should be exchangeable throughout the entire company. However, one ground rule to be followed: The “Approved manufacturer part list” = AMPL is defined globally. Sounds obvious, but it’s not always the case. SAP for example has the functionality to define an AMPL individually for each manufacturing site, which is in my humble opinion super dangerous. More on this in a blog article later.

Should you have seen inventory in factory B, you solved the technical side of the problem. The political dimension is to get a portion of it. Nobody shares stock voluntarily. Get into contact with the first manager level being responsible cross factories. More on AMPL: See this article.

Action2: Are the same manufacturing part numbers (=MPN’s) used under a different CPN?

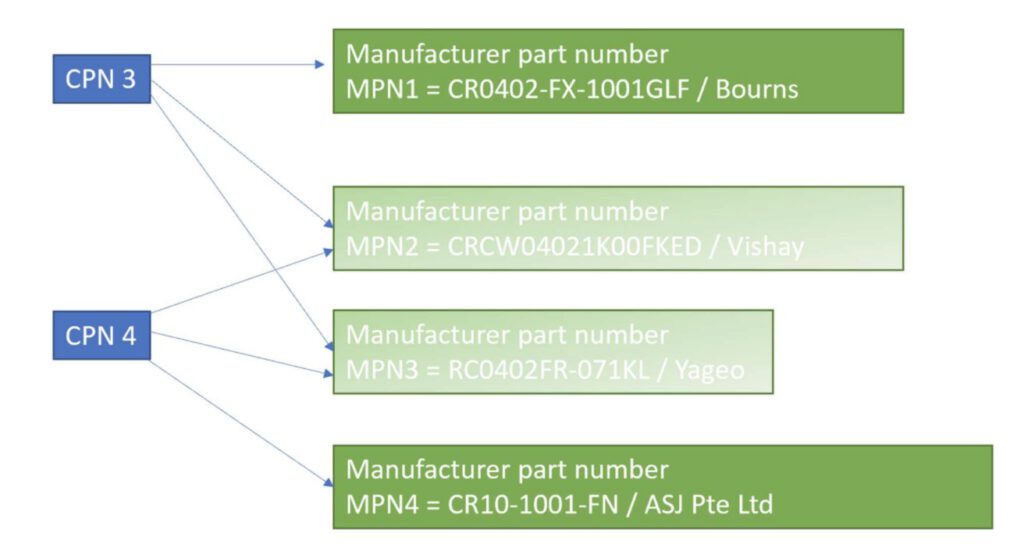

Let’s recap the diagram from the AMPL article

Assume that none of the released manufacturer parts for CPN3 are available. We see that CPN 4 has the 2 middle MPN’s in common. Those 2 can be used immediately without further qualification by R&D. Just check the inventory for CPN 4

Action3: Known alternatives?

3.1: Have other CPN’s released other MPN’s in addition?

Let’s stay at the picture above. You found inventory for CPN4, however the real stock consists of MPN4 – which is not released for CPN3 (yet).

However, the likelihood that it can be used is above 90%. Why? The other CPN has released it already. Or, expressing it mathematically:

If MPN1=MPN2=MPN3 and MPN2=MPN3=MPN4: MPN1 should equal MPN4, so suitable for CPN3 as well. To be verified by R&D of course.

3.2: Any alternatives provided by SiliconExpert?

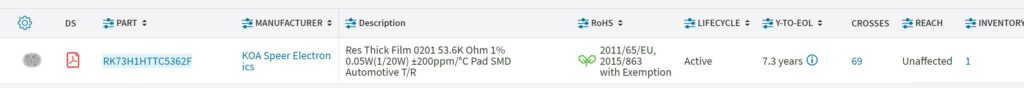

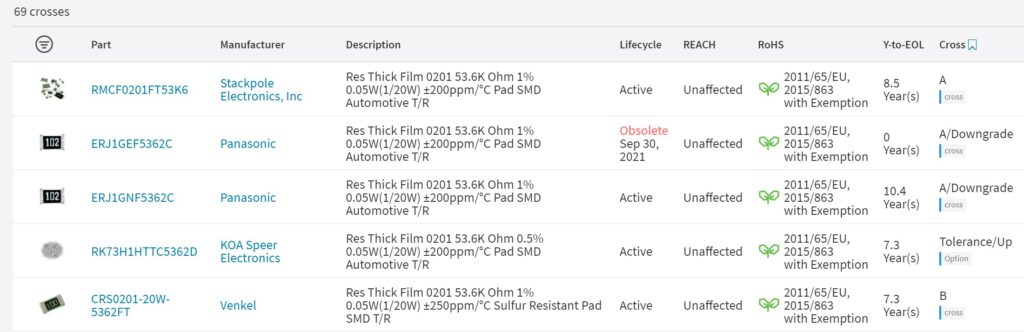

Tools like SiliconExpert are providing you with „crosses and options“ sorted by similarity.

Enter MPN1,2 or 3 into the web frontend, and you will also see an “inventory list”, which is the number of distributors having stock available. Your earlier result might have been 0, otherwise you didn’t have to read this article till here.

But, please also check the column “CROSSES”, sorted by grade:

- „A“: Same form / fit / function

- „D“: A change in the board layout is required as the part has a different footprint

3.3: Contact distributor

Feel free to contact WIN-SOURCE.NET even if they do not list your specific part, they will propose alternatives or might search the market for you.

Action4: Automate your search

You now might have a hopefully longer list of MPNs in hands, which could be used instead (given the thumbs up from R&D). You can now start to type in each single using the search engines….

The more professional solution is to write a tool performing action #1 – #3 for you, and then pushing the results list through all search engines – fully automated.

The buzzword is “API = Advanced programing interface”. Means: Your component engineering server contacts the search engine directly without human interaction. 1 time or 1000 times, computers don’t care.

However, this automation works reliably only if you did your homework from this blog article about data quality

Only MPN’s spelled correctly are understood by the search engines. (well, they try to predict what you meant, but this is not a safe thing). Now you might know why this blog article starts with: “Why is the correct spelling so important”?

All those automations are doable – in lesser time that you might imagine. Just ask me, I’d be happy to help. Also by finding real components.

4.Acts of desperation

4.1: Ask R&D

Well, I used to be an R&D engineer long ago, so I know how an inquiry from sourcing is being processed (or could, but shouldn’t): as an NPI engineer, you are seeing your work in creating cool new and innovative products, not in maintaining old stuff: Old stuff is by NPI definition another word for: “is in production now”.

If you as an NPI engineer are supportive selecting alternatives, you took a risk and you are delaying your NPI project. If you simply say: “Won’t work”: you can go back to your normal work and you avoid risk. If or if not the alternative could have been used: nobody than you could judge.

What as a company can you do?

Split the R&D team into

a) NPI

b) Sustaining and Component & Value Engineering.

You will hear more on this topic in a blog article later if you like. Teaser: What I NEVER saw functioning in my last 27 years being an electronic engineer was:

“let’s our engineers work 80% of their time on NPI and 20% on sustaining”.

What I saw working well: “let 80% of our engineers exclusively work on NPI, and 20% exclusively on Component Engineering, second source qualification, fighting shortages, obsolescence” etc.

4.2: Change the printed circuit board

One of the killer arguments you might hear dealing with second source qualifications is: “This doesn’t fit into the PCB layout, so it is a no-go”. Yes, this is correct in many cases. However, if the situation is desperate enough, a change in layout might pay off. An example could be double-pad layouts 0603 and 0402 for resistors and capacitors. Do you remember the MLCC crisis back in 2019? If you are paying a 6-digit premium on cost even for this chicken food parts, a layout change pays off rapidly.

R&D has no capacity to do it? Well, this is no excuse either. Things like this can be outsourced easily. Ask specialists like Tecnotron. I always had a great experience with Tecnotron, especially with PCB layouts.

4.3: More out of the box solutions

The longer your production is down, the more customer complaints you have – or even customers cancelling orders, the more creative your solutions are getting. Why waiting that long. Start being creative immediately!

“Upgrade alternatives” are almost trivial, such as:

- Tighter tolerance in resistance or capacity

- Wider Temperature range

- Higher voltage limit

- Microprocessors that have more memory, additional (unused) functions

“Downgrade alternatives” could work also:

- Lower power limits, if not needed

- It might apply for a part of your finished goods only.

Adopting the firmware

- Non-released memory chips might not work in your design, simply because the manufacturer’s ID is being pulled as a kind of “whitelist”. So, simply enhance your software!

- The software control sequence for an alternative EEPROM B is slightly different. Well: Try to get an honest answer on this question to R&D: How long will it take to enhance the Software driver?

True story: A memory chip was specified up to 105 deg C, as (only) some of the devices requesting it. Other devices had been built with the same chip also to save additional Company part numbers. Running into shortage, we simply used the cheaper, but available 80 deg C chip for all but the special devices.

Take away:

- A well maintained AMPL mapping list can be the key to success.

- Don’t give up if you didn’t find manufacturer parts released for one given CPN.

- It pays off writing software tools for Component Engineering.

- Finding available parts beyond the AMPL can be a very individual endeavor. Get R&D involved!

- Ask me, I’d be happy to help with:

- Searching available alternatives

- improving your AMPL data quality

- or if you are brave enough: Transforming your R&D