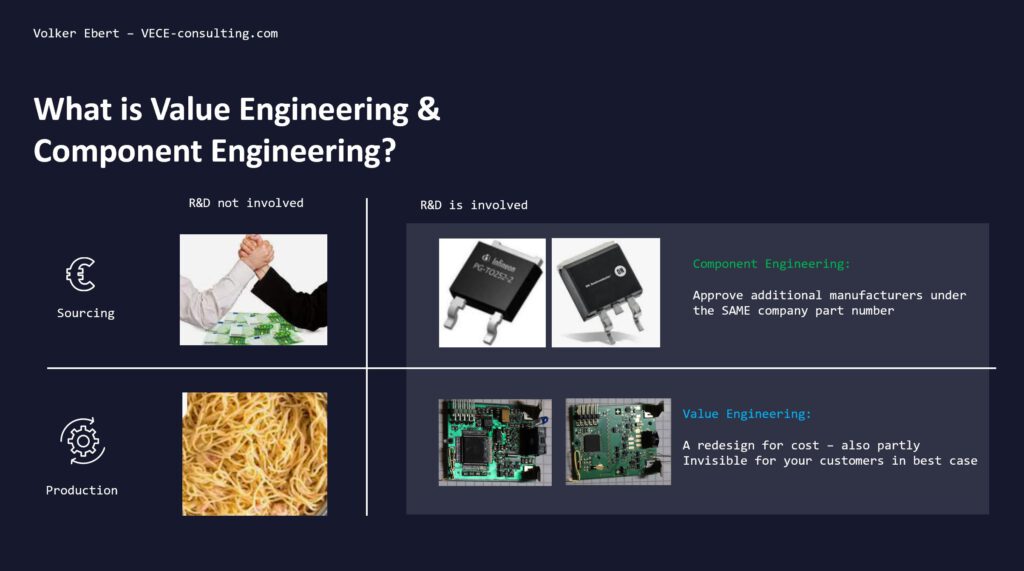

What means: Component & Value Engineering?

Throughout the last years I have seen several definitions for „Component Engineering“ and for „Value Engineering“. Today I will focus on one aspect: Generating additional profit – from which the following definition is derived. Of course, CE and VE have other aspects, more about them in later articles.

My – possibly only partial – Definition of: Component Engineering (=CE):

For one company part number (=CPN), additional manufacturer parts are approved by R&D, or in other words: the AMPL is extended. Once done, sourcing can order any – of course also the newly released and hopefully cheaper – component.

All released manufacturer parts are form-fit-function compatible, they can be mixed in one chute in production or being set up alternately on the pick & place machine.

Component engineering ALWAYS involves R&D. Who else can ensure the correct functioning of a new component in all devices which it is built into. (right side of the picture above). If a cost advantage is achieved by negotiating already released components or by changing the distributor, development does not need to be involved and we are not talking about CE. CE is an additional cornerstone of cost reduction besides price negotiations.

Value Engineering (=VE)

Existing products are modified by R&D, partially or completely redesigned, to reduce manufacturing cost. In the simplest case, this can be the replacement of a single company part number (=CPN) by another CPN, or even a complete redesign. Ideally, invisible to your customers.

Examples:

- Change the carton box – the “trivial VE case”: only one component being exchanged in the bill of material.

- Printed circuit board re-spin from through hole parts to surface mount.

- Exchange the microprocessor

- Optimize the PCB panel to reduce waste.

The picture above shows a real example of an alarm clock. Who spots the 3 areas of optimization?

– PCB on top of PCB, since the original chip was probably no longer available. A VE project would do a re-spin of the PCB to avoid this Babylonian tower.

– Through hole components: VE: Replace by SMD parts to reduce production costs.

– White print: SMT machines don’t read this anyway. Unnecessary.

How to measure success – also in comparison to NPI?

Here is my claim: Component and Value Engineering can be as profitable as NPI. (and, I admit at this point: I have no idea what drug trafficking brings in. But it has at least contributed to your reading this far. Thanks and sorry)

To determine financial success, we need to establish the rules of the game or the formula by which we measure: (Existing cost – new cost) * number of units.

1) What difference do we see in the P&L: (=profit & loss)

a. Due to a successfully completed CEVE project

b. If this project had not been taken place

2) Calculating on incremental profit (not revenue!).

3) Counting the incremental profit over a 12 months period. After that, we still see the financial benefit, but are no longer reporting it.

4) What is the incremental profit per hour worked, or: FTE (=Full time equivalent). Or in other words, if a person works full time on an NPI or VECE project for one year: Which amount of incremental profit was generated?

With these 4 key points, a fair comparison NPI – CEVE is easy.

How does your organization needs to be set up to make it work:

In the last 20 years, I have not seen an R&D department where the left model worked. In contrast, I was able to experience the success of the right model myself (I was the 100% VECE design engineer on the right). Why only the right model works is a longer story. Invite me in for a discussion.

Excuses and arguments:

„NPI generates much more profit than VE and CE“.

My experience over the last 20 years: using fair comparisons (see above) turned out that VECE generates equal profit per FTE, even and especially after finance did the math.

„That’s effort, we’d have to change the PCB“.

Yes, component and value engineering also mean work. But the question was never: „How many resources does that take?“, rather than: What is the return on investment?

In the first picture – bottom right: Value Engineering, the microprocessor was replaced, the PCB layout had to be changed and the software to be ported, one engineering year invested. The price difference was several $$ per unit – with annual volumes of 100,000’s. Just do the math yourself….

“coming down in cost means to scarify quality”

Of course, the quality could be reduced with an alternative component or a redesign. But: „Quality goes without saying“. The new solution must be at least as good as before or better. I have often experienced the opposite: Since a product was touched anyway, small defects that had not been eliminated since then were fixed with the redesign.

Tools:

VE and CE live from ideas submitted. There must be one idea portal where everyone can submit ideas, followed by selecting the most profitable, working them and calculate the additional profit at the end. (more on this in a later blog article).

For Value Engineering, Accolade by Sopheon has proven to be very useful.

For Component Engineering, I have not yet found a suitable tool on the market. My solution was a self-made solution that manages everything from idea input, to workflows, to reporting. Many thanks to Ashwini Singh and Felvin Francis for their ingenious programming work.

Last not least

I am very curious on your feedback.

You don’t believe all that? Give me a chance to evaluate your top 10 components or top 10 finished goods. My first feedback will be: „Challenge accepted“.

Let me support you in setting up your organization for success. Avoid the mistakes I made. Contact me.