Let’s get straight to the point: Component & Value Engineering (CE & VE) is more valuable than dealing with drugs. If you caught my previous article, you’ll know why. But here’s the kicker: if you let the wrong business function take the reins, the entire initiative could end up a costly failure.

Let’s briefly recap what Component Engineering (CE) actually is:

In a nutshell, CE is all about qualifying alternative sources for the components you buy from different manufacturers. That means, as a buyer, you will be able to choose between multiple suppliers for the same company part number (CPN00x) – giving you more flexibility and often lower costs.

Which Business Function Drives CE? Who Does What?

- The proposal to qualify another vendor’s component can come from any department. Often, sourcing will raise the flag, eager to find cheaper components. However, they’re not allowed to make the change on their own, as the new component hasn’t been approved yet.

- R&D steps in to ensure that the alternative component works seamlessly with your finished product. Only once R&D gives the green light is the second source officially released.

- Once approved, sourcing can choose between the original or new component based on price and availability.

So, Who Should Own CE?

Here’s where it gets crucial. R&D does most of the heavy lifting here – they hold the design authority and are responsible for component qualification. For that reason, CE should be owned by R&D.

I’ve seen companies where CE was placed under sourcing, and guess what? It usually didn’t end well. The reason is simple: sourcing lacks the technical expertise for component qualification, and R&D won’t hand over their resources for a process they ultimately control.

Moving On To Value Engineering (VE)

Value Engineering is where things get even more interesting. VE is about redesigning an existing product to reduce costs. Ideally, the customer won’t even notice the change because the product looks and performs the same – but under the hood, it’s a whole new beast.

Whether it’s swapping out a single component or completely reworking the internals, VE always involves updating the bill of materials. If you’re lucky, you can even keep the same SKU. (=Stock keeping unit or product identifier)

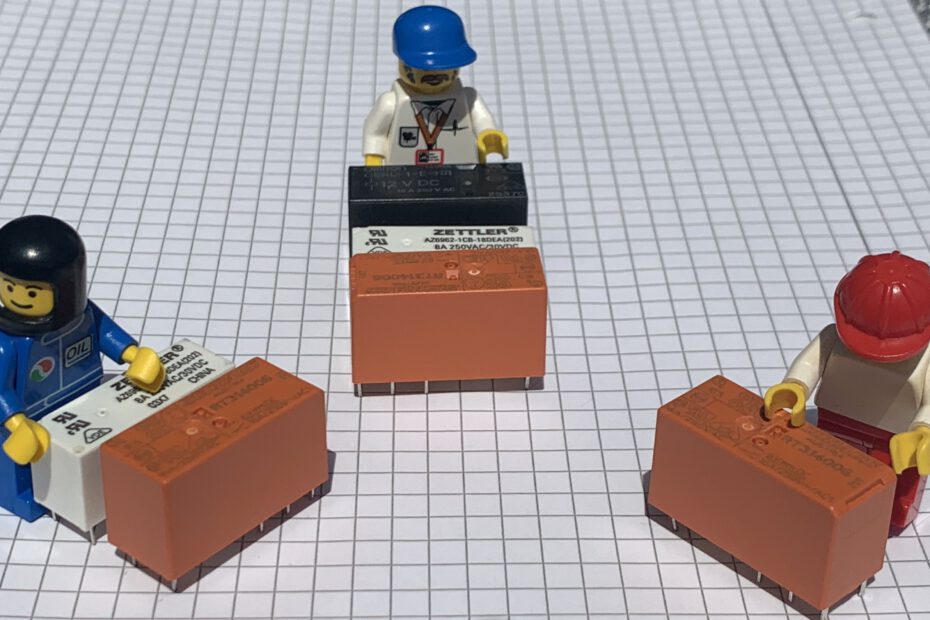

A Simple Example: Swapping One Component

Imagine you swap out one component in a device. That’s the easy case.

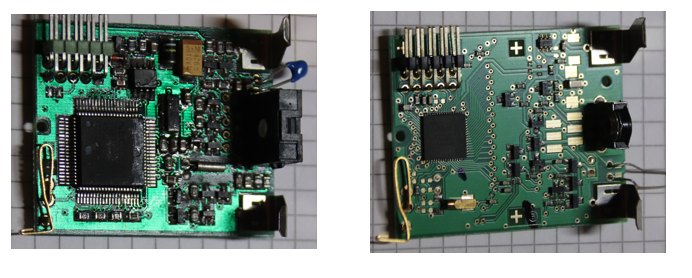

A More Complex Scenario: Redesigning a Whole Circuit Board

Now, picture this: You’ve completely redesigned an electronic board. Most of the components are different, yet the product’s look and feel remain identical to the customer.

For the sourcing team, they’re only concerned with the new components. For production, however, this redesign might feel like a brand-new product launch.

The Key Takeaway

Component & Value Engineering isn’t just another operational task – it’s a highly profitable and strategic business function. If you’re serious about boosting efficiency and cutting costs, you should absolutely consider implementing CE & VE within your organization. But here’s the catch: to succeed, it must be part of R&D.

Don’t make the mistake of leaving it with sourcing. Trust me, I’ve seen where that road leads, and it’s not pretty.

Let’s Talk!

Do you see things differently? I’d love to hear your thoughts – reach out and let’s discuss it.

And if you’re thinking of starting your own CE & VE initiative, let’s chat! With my decades of experience, I can help you avoid the pitfalls and make sure you hit the ground running. Why reinvent the wheel when I can help you steer clear of the same traps I’ve seen?